On-Site Research Facility

At Dayton Artificial Limb, we provide our patients with prosthetic devices that are cutting-edge in the field of prosthetics, due to their on-site research facility and sister-company, Prosthetic Design, Inc. From concept to design to production, we provide our patients with the very best solutions for their particular needs.

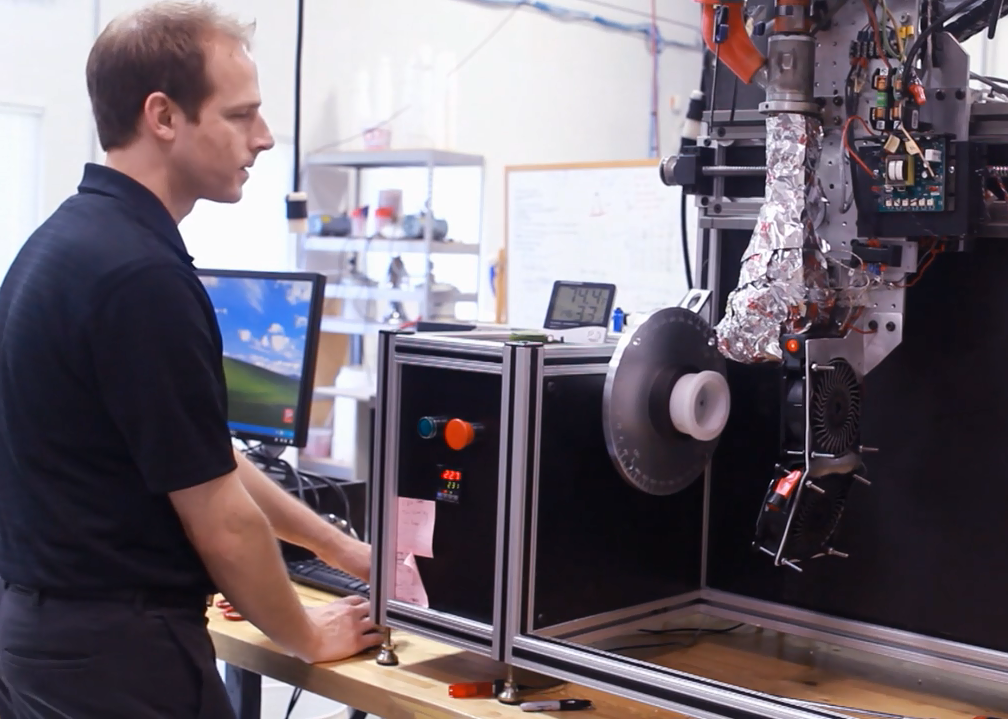

3D Printing Technology

Using PDI’s Squirt Shape 3D Printer, we deliver 100% of our patients with custom, 3D printed sockets! Through research and development, we have streamlined the fabrication process to deliver our patients with their custom device at a fraction of the time compared to traditional fabrication methods.

Custom Silicone Liners

With the assistance of our 3D printer, we are able to fabricate silicone liners in-house. This has had a significant impact on our ability to provide superior care and devices to our patients. In-house fabrication of silicone liners allows us to fit patients quicker. Our liner fabrication process also allows us to customize the shape of the liner to better suite our patients unique needs.

Elevated Vacuum Locking System

We pair the power of 3D printing and Elevated Vacuum Locking System (EVLS) to achieve the most comfortable, secure, and safest prosthesis for our patients.